Polymer

Polymers are all around us. In 2016, the global production of plastics reached 335 million metric tons, and the growing of the industry is continuing at a fast rate. The application of polymers expands to essentially every industry including consumer goods, consumer electronics, automotive and more, and thus effective evaluation of polymer materials through combined testing, imaging, and spectrometric characterization becomes necessary to ensure quality and reliability for long-term use.

Being one of the company’s core business sectors, CarlBerk’s polymer branch offers a full range of analyses to characterize the structure, chemistry, physical and mechanical properties of polymers and polymer-based composites. Our in-house analytical lab is equipped with advanced analytical instrumentation such as Fourier-transformed infrared (FTIR) spectroscopy, gas chromatography-mass spectrometry (GC-MS), differential Scanning Calorimetry (DSC), dynamic mechanical analyzer (DMA), scanning electron microscope (SEM), focused ion beam (FIB) and so on. By combining advanced instruments and problem-solving mindset, we strive to provide one-stop services that run the gamut from basic testing to analyzing complex problems such as:

- Identify matrix and additives in commercial polymer products.

- Determine composition and source of contamination.

- Source of abnormal odor and discoloration.

- Plastic embrittlement and cracking.

- Adhesive failure analysis.

- Evolution of mechanical response with temperature.

- Comparative analysis on material from different vendors/lots.

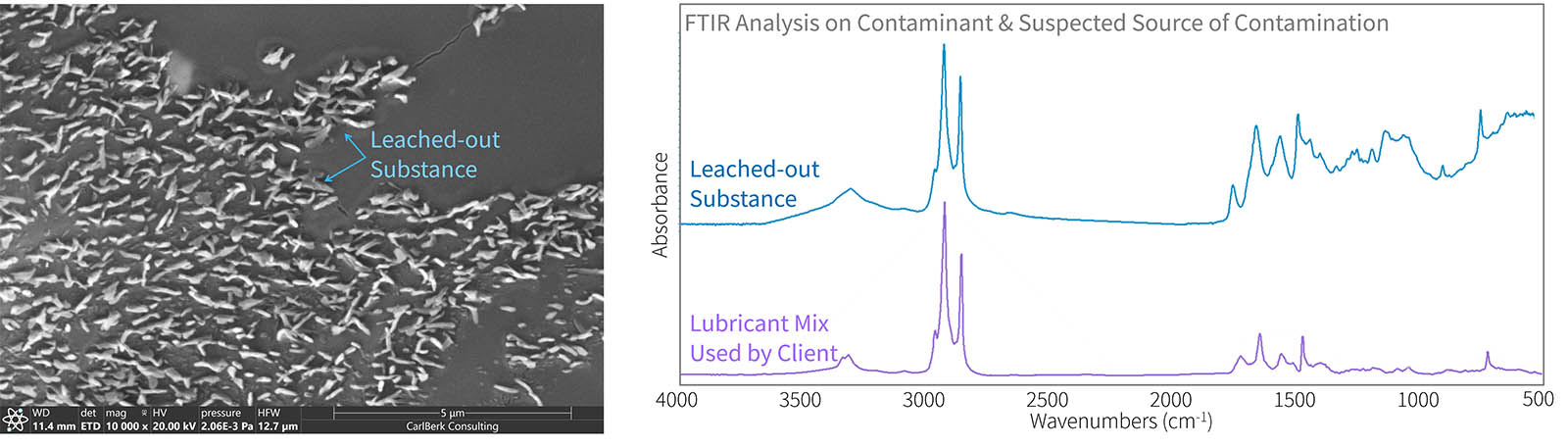

Example 1: Identification of Leached-out Chemicals

Most commercially-used polymers are a complex mixture of base polymer, fillers and functional additives (plasticizer, antistatic, UV stabilizer, mold release, etc.) that could be added either in the raw pellets or during subsequent manufacturing (e.g. injection molding). When additives are incompatible with polymer matrix or are added too much, small additive molecules could leach out from polymer matrix and form surface precipitates. In this example, we successfully extracted the leached-out substance and identified it to be lubricant used by client.

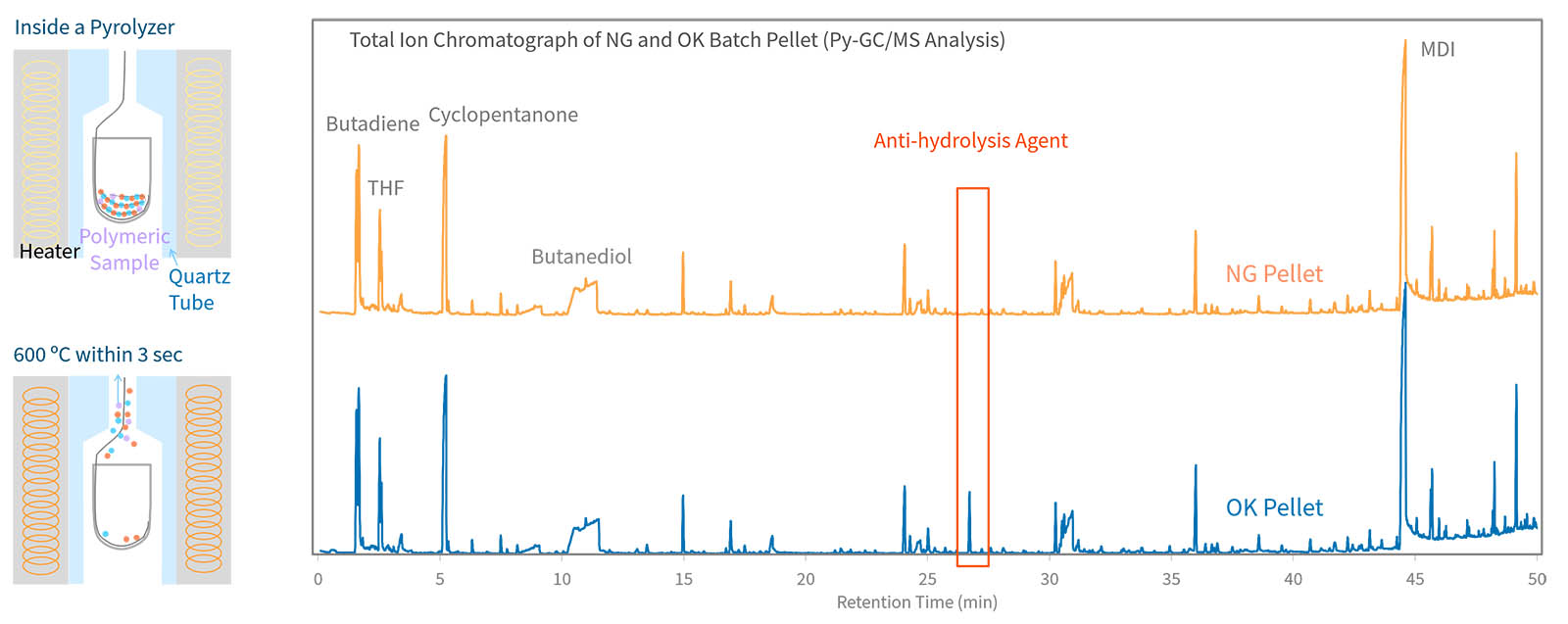

Example 2: Absence of Important Additives in Issue Lot Pellet

Anti-hydrolysis agents are one of the most common additives in polymers, which could prevent breakdown of polymer chains in presence of moisture. By utilizing pyrolysis-GC/MS, we found that the issue batch pellets did not contain enough anti-hydrolysis additive, which led to a degraded property upon storage at high humidity.

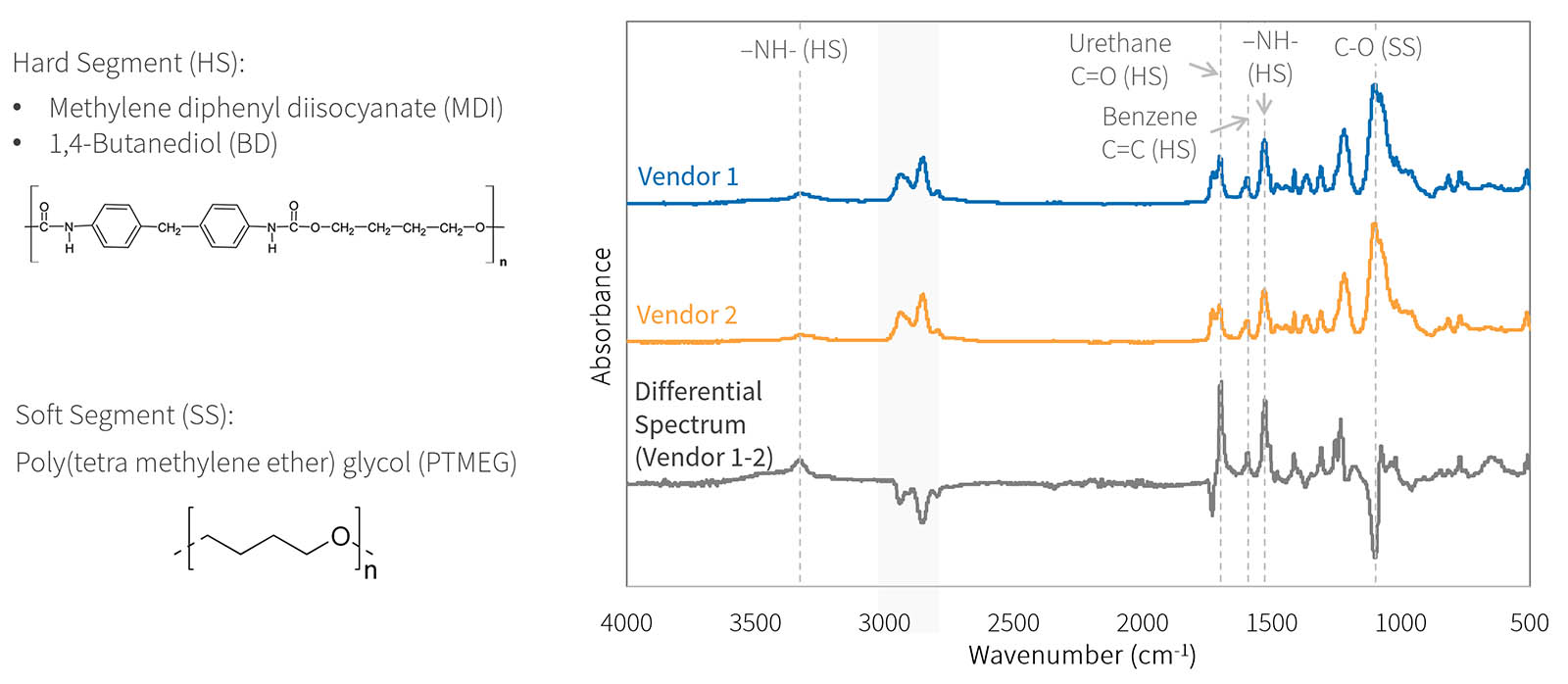

Example 3: Comparative Chemical Analysis of Polyurethane Wheel Manufactured by Two Vendors

Polyurethanes (PU) elastomers are consisted of a soft segment (SS) derived from polymeric diol (polyol) and a hard segment (HS) formed by diisocyanate and low molecular weight diol (chain extender). The mechanical properties of PU are affected by a complex of factors including the structure and chemistry of both HS and SS and interactions between these two segments. In the following example, the relative peak intensities in FTIR spectra suggested a different HS-to-SS ratio between PU wheels manufactured by different vendors.

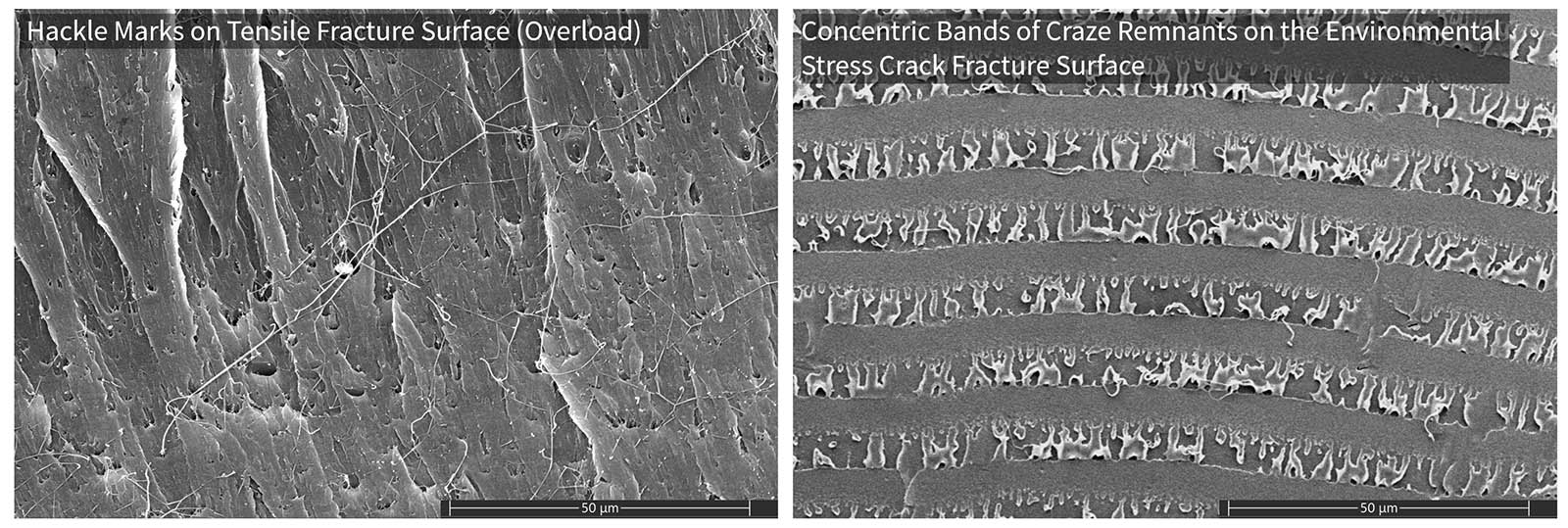

Example 4: Fracture Surface of Polycarbonate Failed under Different Mechanism

A fracture surface not only tells the origin of failure, but also reveals the type of loading that causing the failure. For engineering plastic like polycarbonate, fracture surface created by different loading condition could exhibit drastically different microstructural features.

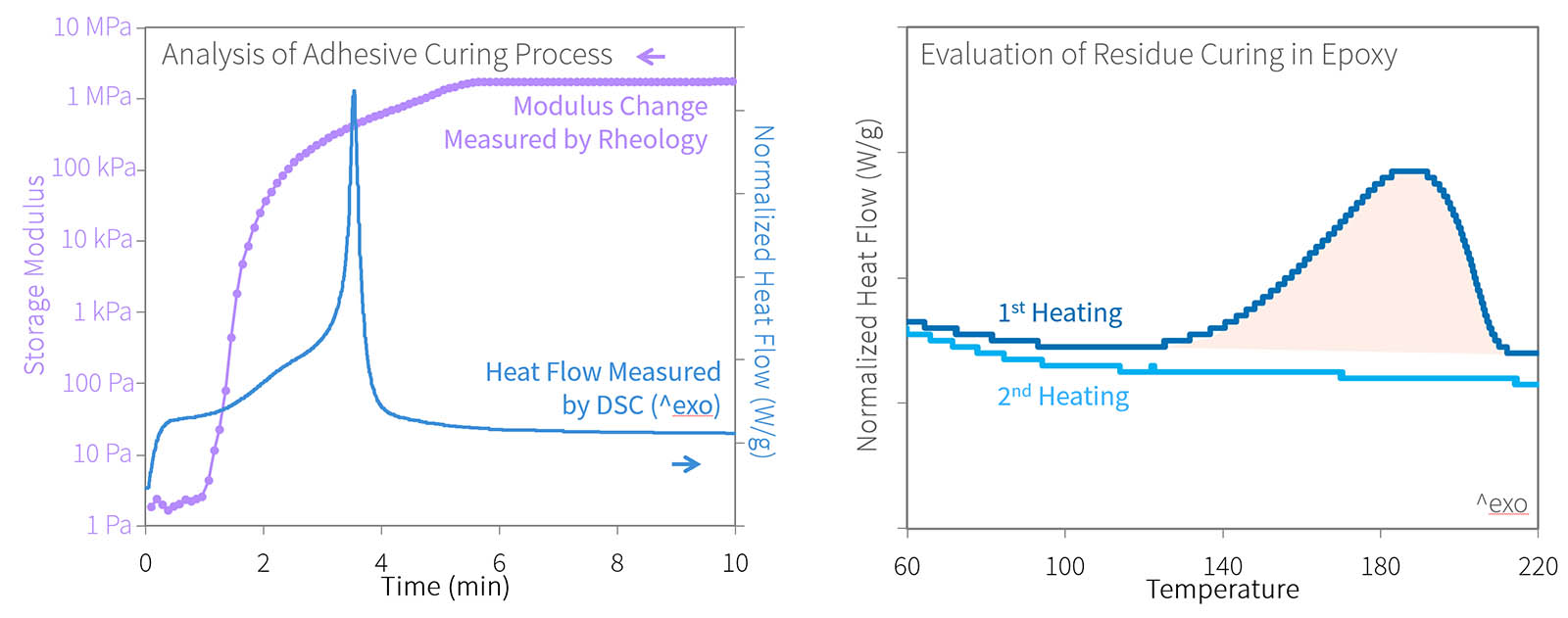

Example 5: Combined DSC & Rheology Analysis on Epoxy Curing Behavior

Despite the wide variety of epoxy resin formula, their curing process was qualitatively similar – at approximate curing temperature, resin viscosity increase as the chemical reactions increase the average length and the degree of cross-linking between the constituent oligomers. Here we demonstrated an example of utilizing differential scanning calorimetry (DSC) and rheology method to analyze the heat flow and modulus evolution during curing process. DSC could also used to evaluate the degree of curing by measuring the heat from residue curing in the 1st heating cycle.